Cabinets: Industrial environments demand robust storage solutions that prioritise safety, security, and compliance. Furthermore, these environments require specialised cabinets designed to handle specific materials and applications. Consequently, understanding the range of available industrial cabinets becomes essential for workplace safety and regulatory compliance.

Understanding Industrial Storage Requirements

Modern workplaces face increasingly complex storage challenges. Additionally, regulations governing hazardous materials have become more stringent over recent years. Therefore, selecting appropriate industrial cabinets requires careful consideration of materials, applications, and safety requirements.

Industrial cabinets serve multiple purposes beyond simple storage. Moreover, they provide essential protection against chemical spills,

access, and environmental contamination. Subsequently, investing in quality industrial storage solutions protects both personnel and valuable equipment.

Medical Storage Cabinets

Healthcare environments require specialised storage solutions for pharmaceuticals, medical supplies, and controlled substances. Furthermore, these cabinets must comply with strict regulatory standards whilst maintaining easy access for authorised personnel.

Key Features of Medical Cabinets

Medical storage cabinets incorporate several critical features. Firstly, they utilise secure locking mechanisms to prevent unauthorised access to controlled substances. Additionally, many models include temperature monitoring systems to maintain optimal storage conditions for sensitive medications.

Moreover, medical cabinets often feature adjustable shelving systems. This flexibility allows healthcare facilities to accommodate various bottle sizes and medical equipment. Subsequently, staff can organise supplies efficiently whilst maintaining easy visibility of inventory levels.

Applications in Healthcare Settings

Hospitals utilise medical cabinets throughout various departments. Emergency departments require rapid access to critical medications, whilst pharmacy areas need comprehensive storage for large inventories. Additionally, treatment rooms benefit from compact cabinets that store frequently used supplies within easy reach.

Dental practices also rely heavily on medical storage solutions. These cabinets store anaesthetics, antibiotics, and other controlled substances safely. Furthermore, veterinary clinics use similar systems to manage animal medications and surgical supplies.

Total Locker Service provides medical cabinets that meet NHS and CQC requirements. These units feature dual-key systems and comprehensive audit trails. Additionally, they offer various sizes to accommodate different healthcare environments.

Key Storage Solutions

Secure key management represents a critical aspect of workplace security. Moreover, effective key storage systems prevent unauthorised access whilst maintaining operational efficiency. Therefore, specialised key cabinets have become essential in many industrial settings.

Electronic Key Management Systems

Modern key cabinets incorporate advanced electronic systems. These solutions track key usage automatically and maintain detailed access logs. Additionally, they can integrate with existing security systems to provide comprehensive access control.

Electronic key cabinets offer several advantages over traditional systems. Firstly, they eliminate the need for manual log books and reduce administrative overhead. Furthermore, they provide real-time alerts when keys are overdue or accessed outside normal hours.

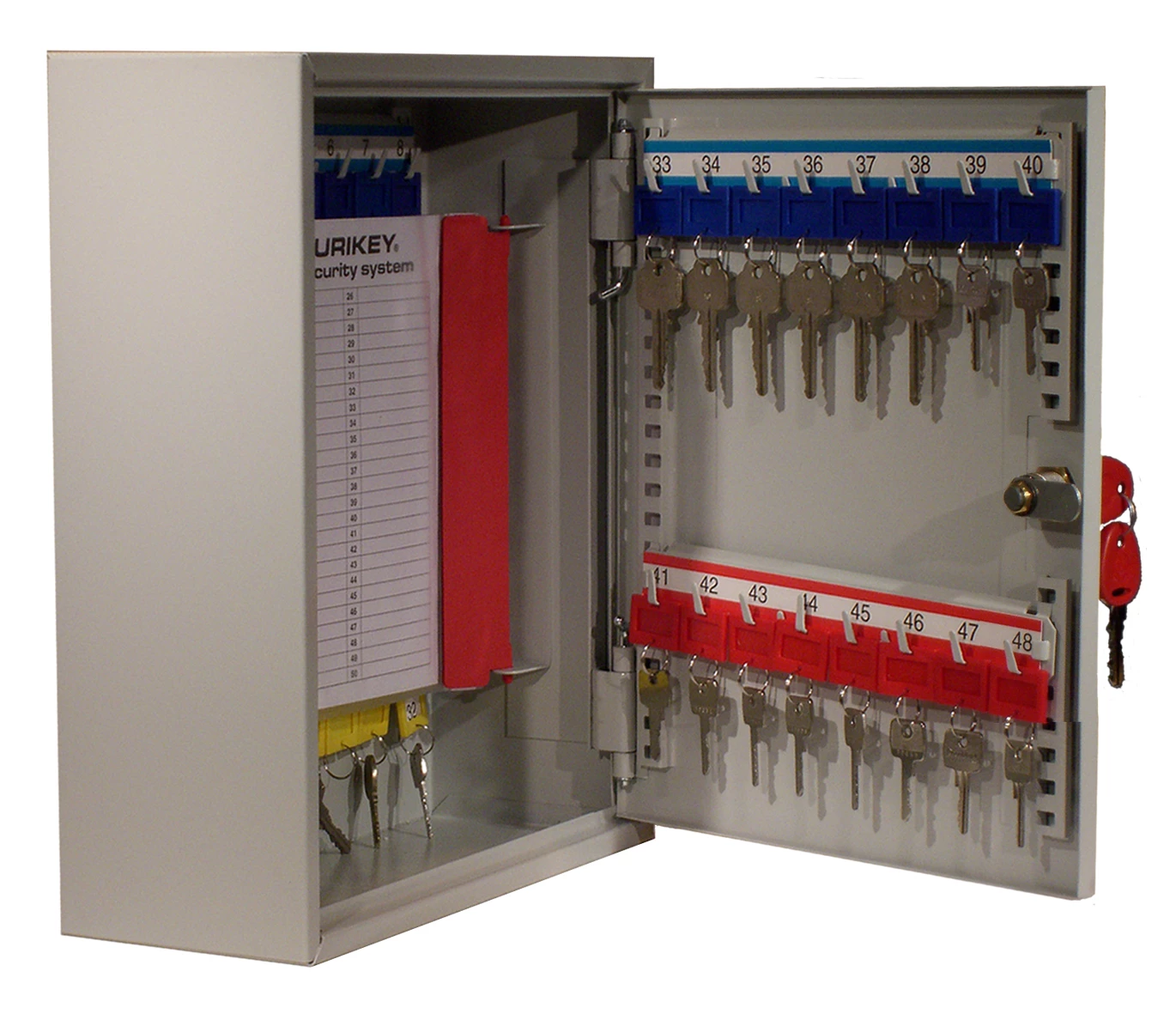

Mechanical Key Storage Options

Traditional mechanical key cabinets remain popular in many applications. These systems offer reliable security without dependence on electrical power. Moreover, they provide cost-effective solutions for smaller organisations with basic key management needs.

Mechanical systems typically feature high-security locks and reinforced construction. Additionally, they include key tags and hooks for organised storage. Subsequently, users can quickly locate required keys whilst maintaining security protocols.

Total Locker Service supplies both electronic and mechanical key storage systems. Their products include audit trail capabilities and tamper-evident features. Moreover, they offer installation and maintenance services to ensure optimal performance.

COSHH Compliance Cabinets

Control of Substances Hazardous to Health (COSHH) regulations require proper storage of dangerous materials. Furthermore, these regulations mandate specific storage conditions for different types of hazardous substances. Therefore, COSHH-compliant cabinets play a vital role in workplace safety.

Understanding COSHH Requirements

COSHH regulations cover a wide range of hazardous substances. These include chemicals, biological agents, and materials that pose health risks through inhalation, ingestion, or skin contact. Additionally, the regulations specify storage requirements based on substance classification and risk assessment.

Proper COSHH storage prevents cross-contamination between incompatible substances. Moreover, it reduces exposure risks for employees and visitors. Subsequently, investing in compliant storage solutions helps organisations avoid regulatory penalties and insurance claims.

Features of COSHH Cabinets

COSHH-compliant cabinets incorporate several essential safety features. Ventilation systems prevent the accumulation of dangerous vapours within storage areas. Additionally, spill containment systems capture leaks before they spread to surrounding areas.

Fire-resistant construction protects stored materials from external heat sources. Furthermore, warning labels and colour-coding systems help identify hazardous contents quickly. Subsequently, emergency responders can take appropriate action during incidents.

Many COSHH cabinets include internal lighting systems for improved visibility. This feature proves particularly valuable in emergency situations or low-light environments. Moreover, transparent doors allow visual inspection without opening cabinets unnecessarily.

Total Locker Service offers comprehensive COSHH cabinet solutions. Their products meet HSE requirements and include detailed documentation. Additionally, they provide risk assessment services to ensure appropriate storage selection.

Personal Protective Equipment (PPE) Storage

Proper PPE storage maintains equipment condition and ensures ready availability when needed. Furthermore, organised PPE storage systems improve compliance rates and reduce replacement costs. Therefore, dedicated PPE cabinets have become standard in many workplaces.

Types of PPE Storage Solutions

PPE cabinets accommodate various types of protective equipment. Hanging systems work well for coveralls, aprons, and high-visibility clothing. Additionally, compartmentalised storage suits smaller items like gloves, safety glasses, and respirators.

Ventilated PPE cabinets help dry equipment after use and prevent odour development. Moreover, these systems extend equipment lifespan by promoting proper air circulation. Subsequently, organisations reduce replacement costs whilst maintaining hygiene standards.

Some PPE cabinets include integrated cleaning stations. These systems allow employees to sanitise equipment before storage. Furthermore, they incorporate disposal facilities for single-use items, maintaining workplace cleanliness.

PPE Cabinet Applications

Manufacturing facilities require extensive PPE storage for various work areas. Each department may need different types of protective equipment based on specific hazards. Additionally, storage locations must provide convenient access without disrupting workflow.

Construction sites utilise mobile PPE storage solutions. These portable units can relocate as work progresses to different areas. Moreover, they provide secure storage in environments where permanent installations prove impractical.

Educational institutions also benefit from PPE storage systems. Science laboratories, workshops, and maintenance areas all require appropriate protective equipment. Furthermore, these cabinets help teach students about workplace safety practices.

Total Locker Service provides PPE storage solutions for various industries. Their products include ventilation systems and adjustable shelving. Additionally, they offer custom configurations to meet specific workplace requirements.

Acid Storage Cabinets

Acids require specialised storage conditions to prevent corrosion, spillage, and dangerous reactions. Moreover, different types of acids have specific storage requirements based on their chemical properties. Therefore, acid storage cabinets must incorporate appropriate materials and safety features.

Construction Materials for Acid Storage

Acid storage cabinets utilise corrosion-resistant materials throughout their construction. Polypropylene and polyethylene offer excellent chemical resistance for most acid types. Additionally, these materials won’t react with stored substances or compromise containment integrity.

Metal components require special coatings or alternative materials in acid storage applications. Stainless steel grades may suit some applications, whilst others require non-metallic alternatives. Furthermore, all hardware must resist chemical attack to maintain security and functionality.

Sealing systems prove critical in acid storage cabinet design. Gaskets and door seals must maintain effectiveness despite chemical exposure. Moreover, they must accommodate thermal expansion whilst preventing vapour escape.

Safety Features of Acid Cabinets

Acid storage cabinets incorporate multiple safety systems. Spill containment prevents leaks from spreading beyond the cabinet interior. Additionally, ventilation systems remove vapours that could pose inhalation risks or create explosive atmospheres.

Emergency eyewash stations often integrate with acid storage areas. These safety systems provide immediate decontamination capabilities in case of accidental exposure. Furthermore, they comply with workplace safety regulations regarding emergency response equipment.

Warning systems alert personnel to potential hazards within acid storage areas. Visual indicators show when ventilation systems operate correctly. Moreover, some systems include remote monitoring capabilities for unmanned areas.

Applications for Acid Storage

Laboratories require acid storage for various analytical procedures and research activities. Different acids serve specific purposes, from sample preparation to equipment cleaning. Additionally, storage systems must accommodate varying container sizes and usage patterns.

Manufacturing processes often require acids for surface treatment, etching, or chemical reactions. These industrial applications may involve larger quantities requiring bulk storage solutions. Furthermore, production schedules demand reliable access to required chemicals.

Water treatment facilities utilise acids for pH adjustment and system maintenance. These applications require storage systems that withstand outdoor conditions whilst maintaining chemical integrity. Moreover, they must integrate with automated dosing systems safely.

Total Locker Service supplies acid storage cabinets for various applications. Their products meet environmental and safety regulations. Additionally, they provide technical support for chemical compatibility questions.

Toxic Substance Storage

Toxic materials require the highest level of storage security and safety features. Furthermore, these substances pose serious health risks that demand comprehensive protective measures. Therefore, toxic storage cabinets incorporate advanced safety systems and robust construction.

Classification of Toxic Materials

Toxic substances encompass various materials with different hazard profiles. Acute toxins cause immediate health effects upon exposure. Additionally, chronic toxins create health problems through repeated or prolonged exposure over time.

Carcinogenic substances require special handling and storage procedures. These materials may cause cancer through various exposure routes. Moreover, reproductive toxins can affect fertility or foetal development, requiring additional precautions.

Some toxic materials also present other hazards such as flammability or corrosiveness. Multi-hazard substances require storage systems that address all relevant risks. Furthermore, compatibility considerations prevent dangerous reactions between stored materials.

Advanced Safety Systems

Toxic storage cabinets utilise sophisticated ventilation systems with multiple air changes per hour. These systems maintain negative pressure to prevent vapour escape. Additionally, they include filtration systems to treat exhaust air before environmental release.

Access control systems prevent unauthorised entry to toxic storage areas. Biometric locks, card readers, and dual-person requirements enhance security. Moreover, these systems maintain detailed access logs for regulatory compliance and audit purposes.

Emergency response systems integrate with toxic storage installations. Automatic leak detection triggers ventilation systems and alerts emergency personnel. Furthermore, suppression systems can isolate areas quickly to prevent exposure spread.

Regulatory Compliance for Toxic Storage

Multiple regulations govern toxic substance storage depending on material types and quantities. REACH regulations require registration and authorisation for many toxic chemicals. Additionally, workplace exposure limits specify maximum allowable concentrations for personnel protection.

Transportation regulations affect how toxic materials reach storage locations. UN classification systems determine packaging and labelling requirements. Moreover, these regulations influence storage facility design and emergency response procedures.

Environmental regulations address waste management and disposal procedures. Toxic storage facilities must prevent environmental contamination. Furthermore, they require monitoring systems to detect potential releases early.

Total Locker Service provides toxic storage solutions that meet regulatory requirements. Their systems include comprehensive documentation and certification. Additionally, they offer ongoing compliance support and system updates.

Locking Systems and Security Features

Industrial cabinet security relies on appropriate locking mechanisms matched to specific applications. Moreover, different environments require varying levels of security based on stored contents and access requirements. Therefore, understanding available locking options helps select optimal solutions.

Mechanical Locking Systems

Traditional mechanical locks remain popular for their reliability and simplicity. Key-operated systems provide straightforward access control without power requirements. Additionally, they offer proven security for most industrial applications.

Combination locks eliminate key management whilst maintaining security. These systems allow access code changes without hardware modifications. Furthermore, they prevent key loss issues that could compromise security or require expensive lock changes.

High-security mechanical locks incorporate advanced features like drill resistance and pick protection. These systems suit applications requiring maximum security levels. Moreover, they often include restricted key systems that prevent unauthorised duplication.

Electronic Access Control

Electronic locks offer advanced features unavailable with mechanical systems. Programmable access codes allow different users whilst maintaining individual accountability. Additionally, these systems can restrict access to specific times or days.

Audit trail capabilities track all access attempts and successful entries. This information proves valuable for security investigations and regulatory compliance. Furthermore, real-time monitoring allows immediate response to unauthorised access attempts.

Card reader systems integrate with existing security infrastructure. Employee ID cards can provide cabinet access whilst maintaining centralised user management. Moreover, lost cards can be deactivated immediately without changing locks.

Biometric Security Options

Fingerprint recognition provides the highest level of user authentication. These systems prevent access sharing whilst maintaining convenience for authorised users. Additionally, they eliminate concerns about lost keys or forgotten combinations.

Advanced biometric systems include anti-spoofing technology to prevent unauthorised access attempts. Live finger detection ensures genuine biometric samples. Furthermore, these systems can require multiple finger verification for enhanced security.

Integration capabilities allow biometric locks to connect with broader security systems. Access events can trigger cameras or other monitoring equipment. Moreover, they can integrate with time and attendance systems for comprehensive personnel tracking.

Total Locker Service offers various locking options across their cabinet range. Their systems include both standalone and networked solutions. Additionally, they provide integration services for existing security infrastructure.

Applications Across Different Industries

Industrial cabinets serve diverse applications across numerous industry sectors. Moreover, each industry presents unique challenges requiring specialised storage solutions. Therefore, understanding sector-specific requirements helps identify optimal cabinet selections.

Healthcare and Pharmaceutical

Healthcare facilities require storage solutions for medications, medical devices, and hazardous materials. Controlled substance storage must meet DEA regulations whilst providing authorised access. Additionally, these facilities need systems for medical gases, chemicals, and infectious waste.

Pharmaceutical manufacturing presents additional complexity with raw materials, intermediates, and finished products. Each stage requires appropriate storage conditions and security measures. Furthermore, these facilities must maintain detailed records for regulatory compliance and quality assurance.

Research laboratories combine multiple storage requirements within single facilities. They need systems for chemicals, biological materials, and controlled substances. Moreover, these environments require flexibility to accommodate changing research programmes and material types.

Manufacturing and Industrial

Manufacturing facilities utilise industrial cabinets for tools, spare parts, and maintenance supplies. These applications require robust construction to withstand industrial environments. Additionally, they need systems that integrate with production workflows and maintenance schedules.

Chemical processing plants require specialised storage for raw materials, catalysts, and intermediates. These substances often present multiple hazards requiring comprehensive safety measures. Furthermore, storage systems must accommodate process scheduling and inventory management requirements.

Automotive manufacturing presents unique storage challenges with lubricants, adhesives, and finishing materials. These facilities require systems that prevent contamination whilst maintaining production efficiency. Moreover, they need solutions that accommodate lean manufacturing principles and just-in-time delivery.

Educational Institutions

Schools and universities require storage systems for teaching materials, chemicals, and equipment. Science laboratories need solutions for various chemicals used in educational demonstrations. Additionally, these facilities must balance accessibility with safety for student protection.

Technical colleges require storage for tools, equipment, and materials used in vocational training. These applications need systems that withstand heavy use by students learning proper handling techniques. Furthermore, they require solutions that support hands-on learning whilst maintaining safety standards.

Research universities combine educational and research storage requirements. They need systems that accommodate both routine teaching and advanced research activities. Moreover, these facilities require flexibility to support changing academic programmes and research directions.

Food and Beverage Industry

Food processing facilities require storage for cleaning chemicals, sanitisers, and food-grade lubricants. These materials must remain separate from food products whilst remaining accessible for operational needs. Additionally, storage systems must withstand washdown procedures and sanitary requirements.

Beverage production presents specific challenges with acids, caustics, and sanitising agents. These substances require compatible storage materials and containment systems. Furthermore, they need solutions that integrate with automated cleaning and sanitising systems.

Restaurant and catering operations require smaller-scale storage solutions for cleaning supplies and chemicals. These applications need compact systems that fit within space constraints. Moreover, they require solutions that accommodate frequent access and restocking procedures.

Total Locker Service Product Range

Total Locker Service provides comprehensive industrial storage solutions across all major applications. Moreover, their product range includes both standard configurations and custom solutions for specific requirements. Therefore, they can accommodate diverse industry needs with appropriate storage systems.

Standard Cabinet Configurations

Total Locker Service offers medical cabinets in various sizes to suit different healthcare applications. These units include dual-lock systems and audit trail capabilities. Additionally, they feature adjustable shelving and temperature monitoring options for sensitive medications.

Their COSHH cabinet range includes ventilated and non-ventilated options for different chemical types. These units incorporate spill containment systems and warning labels for safe operation. Furthermore, they include documentation packages to support regulatory compliance requirements.

PPE storage solutions include both wall-mounted and free-standing configurations. These systems feature ventilation options and adjustable storage compartments. Moreover, they include integrated cleaning stations and disposal facilities for complete PPE management.

Specialised Storage Solutions

Acid storage cabinets utilise chemical-resistant materials throughout their construction. These units include ventilation systems and spill containment features for safe operation. Additionally, they incorporate emergency response equipment integration for enhanced safety.

Toxic substance storage systems include advanced ventilation and access control features. These units provide maximum security whilst maintaining operational efficiency. Furthermore, they include monitoring systems and emergency response integration for comprehensive safety.

Key storage solutions range from basic mechanical systems to advanced electronic management platforms. These systems include audit trail capabilities and integration options for existing security infrastructure. Moreover, they provide scalable solutions for organisations of all sizes.

Custom Configuration Services

Total Locker Service provides custom cabinet design services for unique applications. Their engineering team works with clients to develop solutions that meet specific requirements. Additionally, they provide installation and commissioning services to ensure optimal performance.

Modification services allow standard products to accommodate special requirements. These services include additional shelving, specialised locks, and custom ventilation systems. Furthermore, they provide retrofit services for existing installations requiring upgrades.

Integration services connect cabinet systems with broader facility infrastructure. These capabilities include security systems, building management systems, and inventory management platforms. Moreover, they provide ongoing support and maintenance services.

Quality and Compliance Standards

Total Locker Service products meet relevant British and European standards for industrial storage. Their manufacturing processes include comprehensive quality control procedures. Additionally, they provide certification documentation to support regulatory compliance requirements.

Testing programmes verify product performance under realistic operating conditions. These tests include chemical compatibility, mechanical durability, and safety system functionality. Furthermore, they provide ongoing monitoring to ensure continued compliance with evolving standards.

Technical support services help clients select appropriate storage solutions for specific applications. This support includes risk assessments, compatibility evaluations, and installation planning. Moreover, they provide training services to ensure proper system operation and maintenance.

Conclusion

Industrial cabinets and cupboards represent critical infrastructure for workplace safety and regulatory compliance. Moreover, selecting appropriate storage solutions requires careful consideration of materials, applications, and safety requirements. Therefore, working with experienced suppliers like Total Locker Service ensures optimal outcomes.

The range of available storage solutions continues expanding to meet evolving workplace needs. Furthermore, advances in materials science and electronic systems enhance both safety and functionality. Subsequently, organisations can achieve higher levels of protection whilst maintaining operational efficiency.

Proper storage solutions protect personnel, equipment, and the environment from hazardous materials. Additionally, they support regulatory compliance and reduce liability risks for organisations. Therefore, investing in quality industrial storage represents both a safety imperative and sound business practice.

Total Locker Service provides comprehensive support throughout the selection, installation, and operation phases. Their expertise spans multiple industries and applications, ensuring appropriate solutions for diverse requirements. Moreover, their commitment to quality and compliance provides confidence in long-term performance.

Future developments in industrial storage will likely incorporate smart technologies and enhanced connectivity. These advances will provide even greater levels of monitoring, control, and integration capabilities. Furthermore, they will support more sophisticated inventory management and compliance reporting requirements.

Organisations that prioritise proper industrial storage demonstrate commitment to employee safety and environmental responsibility. Moreover, they position themselves advantageously for future regulatory developments and industry best practices. Therefore, selecting quality storage solutions represents an investment in long-term success and sustainability.